Megatrend material innovations

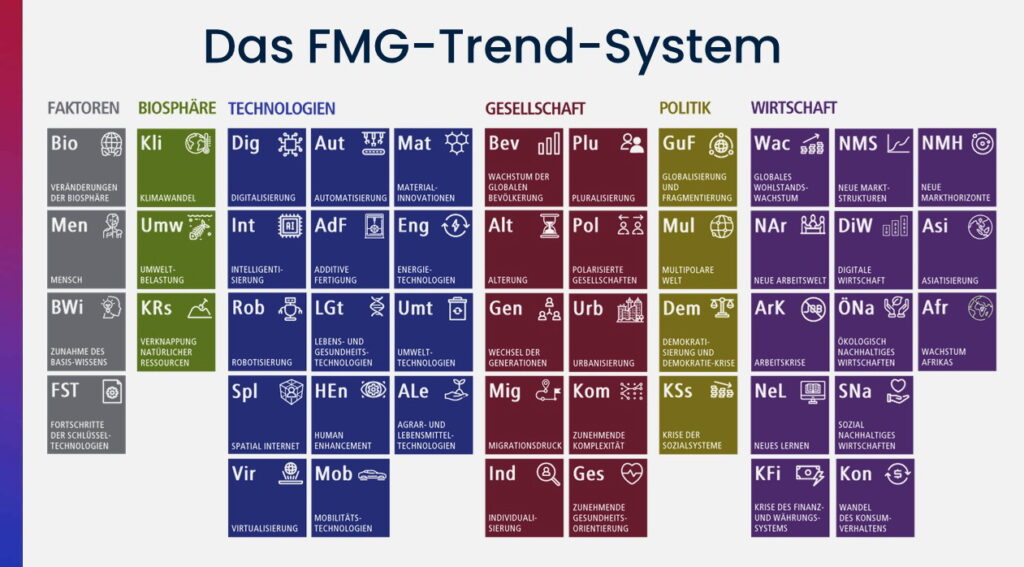

From the FMG Trend System: For your future-proof company

Material innovations are crucial for many future markets

The megatrend of material innovations is fundamentally changing industrial value creation. New materials are opening up technical possibilities, driving digitalization, the energy transition and the circular economy – and creating the conditions for more efficient, more sustainable and more intelligent products.

The development of these materials is based on advances in nanotechnology, bionics, artificial intelligence and simulation. Companies that understand and exploit this megatrend at an early stage not only gain technological advantages – they also open up new markets and secure their future viability. To the overview of all megatrends

What do material innovations mean for companies?

Material innovations are no longer just a research topic, but a strategic competitive factor. In numerous industries, from automotive to construction to medical technology, pressure to innovate is arising that is changing not only products but entire business models.

New materials enable differentiated offerings with improved performance, sustainability or customizability. Advanced materials lower energy consumption, reduce emissions and enable maintenance-free operation. Digital material development accelerates innovation processes and reduces development risks.

- Alongside human motives, material innovations and other technologies are the strongest trends driving change. We use our tools to shape the world, mostly to our advantage.

- The megatrend of material innovations is just one of many that could be relevant for the future of your business.

- In addition to megatrends from the biosphere, society, politics and the economy, FMG’s trend system also includes the drivers that trigger trends such as material innovations, the future factors. To the overview of all megatrends

Four key developments in material innovations

1. sustainable and bio-based materials

Sustainable materials enable a resource-saving, environmentally friendly and recyclable industry. They help companies to achieve ESG goals and meet regulatory requirements.

Aspects of this development:

Bio-based plastics are made from renewable raw materials and reduce dependence on fossil resources.

Bioengineering uses biological principles to develop efficient, structured materials modeled on nature.

Biointeractive materials enable sensory interaction with living systems, for example as wearable or implantable medical technology.

Recyclable materials can be efficiently returned to the material cycle after use.

Wood-plastic composites combine technical performance with the environmental compatibility of natural fibers.

Superabsorbents can absorb 1,000 times their own weight in liquid and are used, for example, in environmental protection.

Nanopaper is extremely tear-resistant and lightweight and represents a potentially sustainable alternative to conventional paper.

Spider silk is an extremely resilient, biocompatible protein structure that can be produced industrially in the future.

2. intelligent and adaptive materials

Smart materials actively adapt their properties to their environment. This opens up new possibilities for smart products, adaptive surfaces and autonomous systems.

Aspects of this development:

Chameleon plastics change color under pressure or temperature and serve as optical sensors, for example.

Electroactive polymers deform under tension and can be used as “artificial muscles”.

- Disposable electronics are based on printed, inexpensive electronic components that can be disposed of after use.

Shape memory materials return to their original shape after deformation as soon as they are activated.

Intelligent textiles contain integrated sensors or actuators and enable new functions in clothing and medicine.

Phase change materials (PCM) store heat during phase transitions and release it again when required.

Photocatalytic materials purify air or water by converting UV radiation into chemical reactions.

Self-healing materials automatically close cracks by means of embedded microcapsules or external triggers.

Magnetostrictive materials react mechanically to magnetic fields or generate them when deformed.

Programmable matter can change its properties or shape via software on the basis of molecular structures.

Affective materials react to emotional or sensory stimuli – still a young but growing field.

3. nanomaterials and molecular structure control

Nanotechnology opens up completely new dimensions for materials – targeted manipulation at an atomic level creates properties that are impossible on a macro scale.

Aspects of this development:

Carbon nanotubes are carbon-based tubes with extreme strength and conductivity.

Graphene is a two-dimensional carbon material with revolutionary electrical and mechanical properties.

Fullerenes are spherical molecules that open up new possibilities in optics, chemistry and medicine.

Metal-Organic Frameworks (MOFs) store gases and serve as filters or catalysts.

Nanocatalysts increase the efficiency of chemical processes through greatly enlarged reaction surfaces.

Nanoceramics are characterized by high strength, transparency and temperature resistance.

Stealth materials specifically deflect electromagnetic waves and theoretically make objects “invisible”.

Superlenses break through the classic resolution limit of optical systems.

Boron nanocoatings offer extreme wear and oxidation protection on metallic surfaces.

Colossal Carbon Tubes (CCTs) combine low weight with extreme strength and conductivity.

4. lightweight construction and digital material development

Materials are being designed to be smarter, lighter and more precise – based on digital modeling and additive manufacturing. This is radically changing development, production and integration.

Aspects of this development:

Carbon fiber composites combine very high strength with extremely low weight.

Glass fiber composites offer high chemical resistance and mechanical flexibility at comparatively low cost.

Aerogels are extremely light, highly porous materials with excellent insulating properties.

Metal foams are energy-absorbing, lightweight and are used in crash protection, for example.

Designed materials are created on the computer and are specifically simulated for certain properties.

Polymer electronics uses conductive plastics for flexible, cost-effective electronics.

Printed electronics enable electronic circuits to be printed on film or paper.

Stretchable printed circuit boards can be integrated into textiles and wearables.

Organic semiconductors open up new applications for OLEDs, displays and solar cells.

Surface computing & nanotouch turn material surfaces into interactive user interfaces.

Conclusion: Using material innovation as an opportunity for future markets

The megatrend of material innovations is not only changing products, but also the business models of many industries. The ability to achieve greater performance with less material is becoming a prerequisite for technological leadership and sustainability.

Companies can use new materials to develop differentiated products and open up new markets.

Intelligent materials enable greater efficiency, functionality and new value propositions.

- With the Future Radar Program, you can identify how material innovations will become relevant for your company in the future and how you can use them as a strategic opportunity.