Enno Däneke

The long-term vision of 3D printing logistics is, of course, the replicator as seen in Star Trek. Unfortunately, we are still a long way from that. Why? Because to do that, we would have to print at the molecular level and at the elemental level. For this purpose, every element that can potentially occur in a product must be in stock. Accordingly, the entire periodic table and that is not possible today and also unrealistic in the foreseeable future. If at some point we can restructure atomically, or at least molecularly, then we will get closer. Although the first printers are available that can print out diverse materials at the nanoscale. From today’s point of view, we are still far away from the real replicator, especially if you want to implement large-scale applications.

But: 3D printing will massively change logistics in the coming years.

Additive manufacturing in the spare parts industry

3D printing plays an important role for logistics service providers in several places. The obvious application is in spare parts logistics. The use here has been current for some time. There are initial approaches where 3D printers are used for spare parts logistics such as in the shipping industry. For example, 3D printing centers have been set up in various ports that can supply the maritime industry with spare parts in a very short time, depending on demand. The effort is worth it because of the great financial leverage that a time advantage brings to this business. Even short downtimes of a ship incur immense costs. Collaborating with local printing centers pays off enormously from a purely economic point of view.

Sharply declining costs of 3D printing logistics

What we’re going to see in 3D printing logistics over the next few years is a shift in the boundaries of what makes economic sense. They always shift downward. So there will be more and more areas where 3D printing will be financially attractive. This means that in terms of cost, 3D printing will be able to keep pace in more and more areas with the classic manufacturing processes we have known up to now. Flexibility and speed are other advantages that 3D printing can bring to logistics.

In search of new fields of application

What is needed for 3D printing in the field is local printing infrastructure. A field of opportunity is emerging for logistics service providers. The question is: Will it be worthwhile in the future for production companies and plant manufacturers to set up their own printing centers and spare parts production facilities if it is possible to hand over these orders to logistics service providers who specialize in 3D printing?

Specialization can result in cost advantages because each company individually would not be able to demonstrate full utilization of the 3D printers. Logistics service providers could offer an exciting alternative to warehousing or short-notice ordering by airmail with a local or global network of print centers.

The question is: when will this business model become real and what is its scale? And which segments are the first to be interesting?

Processes in which high speed is crucial and downtime must be avoided at all costs are of particular interest. In the search for possible pioneer industries, it is therefore necessary to analyze where the opportunity costs are highest when plants are idle. Where is the greatest effort to store a large number of spare parts? Where are very durable machines used? After all, decades of stockpiling spare parts could also be avoided through digitization and 3D printing.

With such questions, products and markets can be found for which the benefit of using 3D printing logistics is particularly high. These will then be the areas in which a printing center will gradually complement and then replace classic warehousing.

It is unlikely that 3D printing will enable the complete elimination of inventory in all areas – at least not in the next few decades. For this purpose, the quantities are much too high in many industries and the large economies of scale in classic production technologies make it impossible for 3D printing to keep up for the time being.

But it is also a fact that the possibilities and the materials we can print are becoming more and more diverse. The complexity and functionality of the parts is also increasing. In the meantime, we can, for example, already print necessary electronics directly. This means that the range of applications will increase and the costs of production will fall rapidly and sharply. Logistics service providers must therefore also ask themselves at which points flows of goods are eliminated or become fewer. And where, on the other hand, new flows of goods are being created by the 3D printing economy.

Do production-related logistics companies need to adapt more to 3D printing?

Basically, it’s not just about supplying spare parts, but about completely rethinking production. 3D printing and other additive processes can be used to produce products in their entirety. That is, they are no longer assembled from components. This is made possible by integrating functionality with printed electronics, moving parts, complex geometric shapes and new material combinations.

This results in a new way of looking at the supply chain. There will then no longer be a need for hundreds of suppliers to deliver individual parts, which will be reassembled into systems that will eventually result in a final product.

Instead, you can produce directly at the system level. In the automotive industry, for example, it will be possible to print a complete chassis in one step, including all functions. The interior and other interfaces between man and machine could also be simply “printed out”. The advantages of this would be the massive reduction in individual parts and the reduction in the complexity of the entire production.

3D printing logistics for large components

In addition to research & development on small parts and the continuous optimization of material usage with 3D printers, large objects are also becoming more and more interesting for 3D print production. One example is gantry solutions through which the workpieces pass and are built up piece by piece in this gantry. This will make it possible to produce parts of unlimited size.

It will be exciting in the next few years and the first applications will come to market. For the time being, this will be the case in niches before large-scale applications become possible and large parts can be created. Additive manufacturing processes can be a very interesting alternative, especially for large parts that are often produced in smaller quantities.

Opportunities for logistics service providers in 3D printing

In summary, the biggest opportunities for logistics service providers are in spare parts logistics, rare large parts, integrating functionality into printing, and completely rethinking global supply networks.

Follow these links as well:

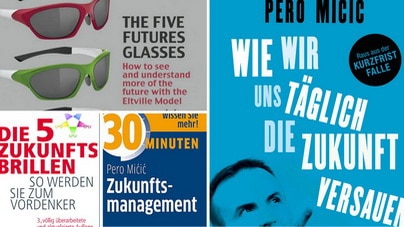

► The Future Strategy Program for SMEs

► Free video crash course THE FUTURE OF YOUR BUSINESS

► BUSINESS WARGAMING for robust business and future opportunities

► KEYNOTES by Pero Mićić for your employees and customers

Have a bright future!